FUJITSU GENERAL Group

All Fujitsu General plants are ISO 9001 certified and operate under a unified quality control system. We deliver to customers all over the world high quality products that have passed stringent quality inspections.

We require all our parts suppliers to submit test reports to ensure that all parts we receive from them meet our quality standards. Our in-house test department inspects incoming parts to ensure their compliance with RoHS as required by the EU. We also conduct 100% inspection of main parts to prevent defective parts from making it to assembly lines.

We carry out stringent quality inspections in all production processes performed in our plants.

To keep the quality of our products high, inspectors check their quality from start to finish on production lines.

The Group's 5 overseas production subsidiaries are individually certified with ISO 9001 and ISO 14001.

The Group's 11 overseas sales subsidiaries are certified with ISO 14001.

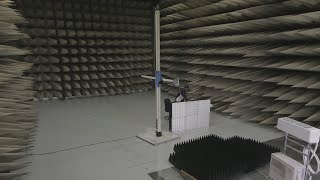

We are streamlining the trial production and evaluation of high-quality, high-performance, and highly comfortable products utilizing data and simulations that visualize airflow, noise, vibration, etc. from air conditioners. In addition to the conventional technology development such as room temperature and airflow control, we continue to work on the development and new technology to realize further comfort, proceeding with various verifications on the relationship between the sensible temperature and the feeling of warmth and coldness of each part using thermal mannequins and subjects.

Sound on - 0:50

Sound on - 0:44

Sound on - 0:36

Sound on - 0:39

Sound on - 0:33

Sound on - 0:37

Sound on - 0:32

Som ligado - 0:44

The 60m height difference test tower is a facility makes mounting tests under installation conditions where the height difference between the indoor unit and outdoor unit of the air conditioner is large.

Sound on - 0:28

Sound on - 0:39

GLOBAL | English

GLOBAL | English